.

REPAIRS & SERVICES

In the 28 years we have had our workshop in Hamburg-Altona, a multitude of clients have entrusted us with their instruments for revision, adjustment and repair.

Even if the instrument is not broken, all the components of your instrument and bow need to be checked and maintained on a regular basis to ensure optimal playability at all times. Well-maintained string instruments can enjoy an incredibly long life span!

We have invariably found our customers' demands and questions in this respect both demanding and inspiring.

Our business is designed to be a full service workshop; in other words, we provide you with all the services your string instrument requires through the years.

To ensure a string instrument or bow remains optimally playable in the course of its long life, all of its components need to be checked, serviced, and overhauled on a regular basis. Such normal repairs include:

- cleaning and polishing the varnish

- glueing of open seams, fingerboards and necks

- new bridges and soundposts →sound adjustment

- fitting of new pegs or refitting of your existing pegs

- solid bushings and spiral bushings

- shooting and polishing fingerboards

- making and glueing of new fingerboards out of ebony or Corène©

- correction of fingerboard elevation or resetting the neck

- neck grafts ( if the neck is broken )

- cleaning and glueing of cracks

- fitting and glueing new bassbars

- fitting patches in tops and backs (such as sound post patches)

- retouching the varnish and other work on the varnish

- as well as →bow repairs.

.

RESTORATION

Violins, violas, cellos, and their bows are primarily musicians' daily tools, and thus inevitably subject to a fair amount of wear and tear. But apart from this, master instruments are also works of art we need to safeguard for future generations.

They have to be kept in intact and optimal condition to ensure that their sound and their long-term value are maintained.

As violin makers, our task is to ensure the preservation of a master instrument’s structural strength, its aesthetics, and its personal timbre. Thus we treat your master instrument as a historical work of art.

Occasionally, when an instrument has suffered major accidents or has been poorly repaired after previous damage, it is in need of major restoration. We use the term “restoration” if not just one flaw requires attention, but an entire area of the instrument is affected.

In the course of a restoration, we can stabilize cracks, rebuild and reinforce sunken archings, or clean and refill certain areas where the varnish has worn away. While restoring the instrument’s structure and appearance, we apply the greatest care to preserve its original substance.

We can look back on over 25 years of experience in string instrument restoration. If your instrument is in need of a major workover, feel free to contact us.

.

SOUND ADJUSTMENT

String instruments change considerably with the passing of time: a setup that worked well several years ago may start delivering less than optimal results if it is used in a different climate zone, or simply due to usage.

We start any sound adjustment by drawing up a record of the instrument’s current condition, to be able to return to it if necessary. Then, consulting with the customer, we modify the setup, play and listen to obtain improved sound or playability.

One important thing is to maintain a continual overview of the instrument as a whole. So it´s necessary to close open seams and cracks first, as well as to re-glue loose necks and fingerboards, before moving on to more delicate sound adjustments.

Sound adjustment may comprise moving the soundpost and bridge, changing the strings and accessories (the tailpiece, the tailchord, the finetuners or the endpin of the cello), or modifying the bridge. All these parts contribute to the sound of the instrument!

Sound adjustments are only carried out by appointment. Like all other repairs, they are invoiced according to the amount of worktime and material invested.

.

ANNUAL CHECK-UP

Violins, violas, and cellos normally don´t lose any of their value if regularly adjusted and well-kept. In fact, years of playing can actually increase the beauty and lushness of their tone and increase the range of expression. But the instruments need to be kept up on a regular basis, since bridges, soundposts, fingerboards, strings, and pegs are subject to constant wear and tear. Your instrument’s varnish also needs to be regularly checked and maintained for it to keep its beauty and fulfil its protective role.

If you are a professional, we recommend that you bring in your instrument once a year for check-up and re-adjustment. Amateur musicians may bring in their instrument for check-up and adjustment every two years, depending on how often they play.

We check all components and glue-joints one by one: is the soundpost still fitting well? Has the bridge warped? Do the pegs fit and turn well? Everything is going to be surveyed and eventually fixed to attain optimal condition.

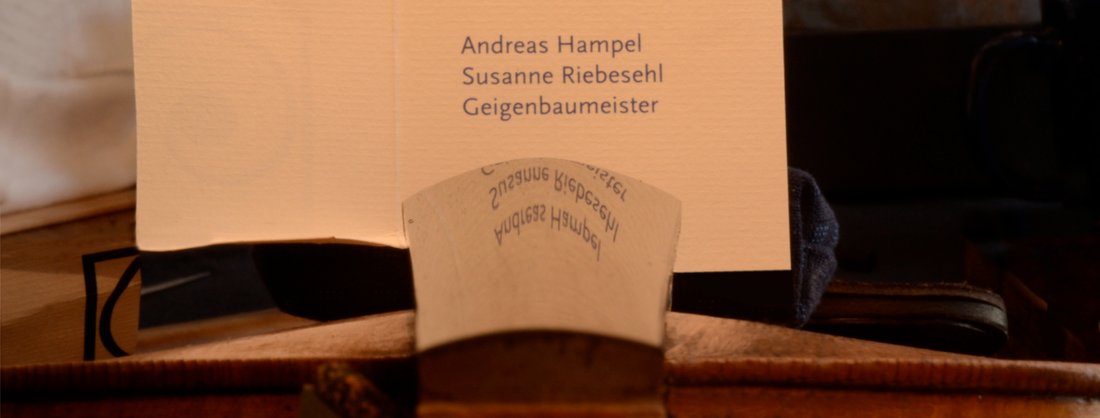

One of the regular jobs done at a check-up is re-shooting the fingerboard and finally polishing it to a shine (see the above picture).

If your strings are played demandingly, they should be changed at least once a year. The material for today’s strings is extremely resistant, so they hardly break in normal use. Nevertheless, any string will eventually lose its tone power and won´t be able to be played in perfect fifths with the passing of time.

The varnish needs to be completely cleaned at regular intervals; spots where the wood is unprotected need to be sealed off with protective varnish. As the upper treble bout rib is frequently in contact with the hand and very subject to wear, we recommend a rib protection film for that area.

We also closely inspect your bow; we inspect the evenness of the hair ribbon, the thumb area and thumb leather, the bow mechanics eventually needs to be readjusted, and spots where the varnish has worn out need to be repolished.

.

BOW SERVICES

For a musician, the bow is a highly personal item of great importance: it feels like the music-making prolonged hand of the player.

So it is extremely important to maintain it in optimal condition.

- with best-quality hairs which grab the strings well (see below)

- with a symmetrically distributed band of hairs in order to have the same amount of traction on the left and on the right.

Each time a bow is brought in for maintenance, we check the condition of the stick, the the bow tip, the screw and eyelet, and the thumb leather. Slight divergences can be easily corrected at the onset: in doing so, we can avoid greater damage in the long run.

• Each Thursday is “bow day” at our workshop. Leave your bow with us either on Wednesday, or else bring it in on Thursday morning between 9 and 10 AM, and if you need it rehaired, or the thumb leather or eyelet replaced, it will be ready by the same evening.

For more extensive repairs (such as cracks or bow tips), please make an appointment.

• Regarding bow hair, we could write an entire chapter…

In our view, the best bow hair currently comes from Canada. These hairs are somewhat stronger; they are chemically untreated, and have a granular surface structure that doesn’t slip, but takes the rosin well and adheres well to the strings. They produce a full-bodied, “creamy” sound, with very little noise, and maintain their adherence to the strings for a considerably longer time than other varieties. They also tend to break less than the thinner Mongolian hair.

Each bundle of hair we receive is tried out on our own bows in order to give us an impression of its playing quality and its sound.

• Bow tips: since ivory is internationally protected, we replace broken bow tips with a new synthetic material: Tip-Armor®, made out of a fabric-reinforced polymer. Tip Armor® is more stable than ivory and can be formed into beautiful classical shapes. And due to its discreet farbric pattern customs officials will easily recognize that the material is quite evidently not ivory.

• Thumb leather: to replace damaged thumb leather, we exclusively use European goatskin leather, available in different varieties and in several degrees of rigidity.

• Inner mechanism / screws and eyelets: old eyelets are often made of brass, which eventually wears off after years of use. When replacing a worn-out eyelet, we control and correct the geometrically correct alignment of screw and eyelet to ensure the mechanism runs smoothly, with as little abrasion as possible. For new eyelets we use bronze, which is much more rigid and durable than brass.

• Warping: if a bow stick warps off to the left or right, that's usually because the hair has worn off too much on one side. So, if twenty hairs have broken on the playing edge, the remaining hairs will pull the bow-stick off-center every time you draw it across the strings. In such cases, a rehair is immediately called for, in order to rebalance the tension on the bow.